Power Stop brakes revolutionize automotive safety and performance with advanced hydraulic technology, offering precise control for consistent braking. Ideal for demanding driving conditions, these brakes extend component lifespans but require regular maintenance, including fluid levels checks, corrosion prevention, and adherence to manufacturer schedules, to ensure optimal efficiency and safety.

Power Stop brakes have gained popularity among automotive enthusiasts due to their potential benefits in enhancing braking performance. This article delves into the world of Power Stop brakes, offering a comprehensive understanding of their definition and basic functioning. We explore the impact on brake wear, highlighting advantages and potential disadvantages. Additionally, we provide essential maintenance tips to optimize their lifespan and minimize wear, ensuring your vehicle’s safety and reliability. Discover how these advanced braking systems can revolutionize your driving experience while promoting efficient brake management.

- Understanding Power Stop Brakes: A Definition and Their Basic Function

- The Impact on Brake Wear: Advantages and Potential Disadvantages

- Maintenance Tips for Optimizing Power Stop Brakes' Lifespan and Reducing Wear

Understanding Power Stop Brakes: A Definition and Their Basic Function

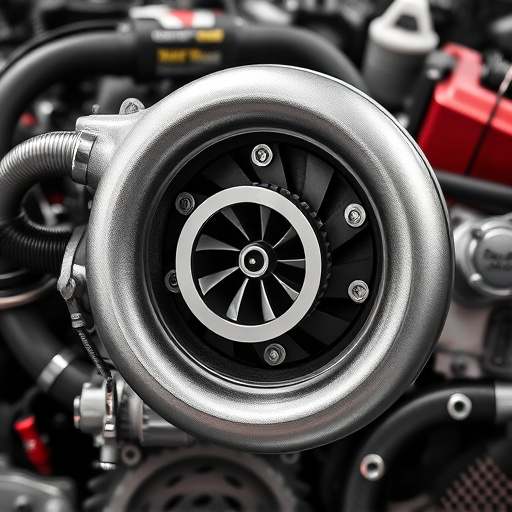

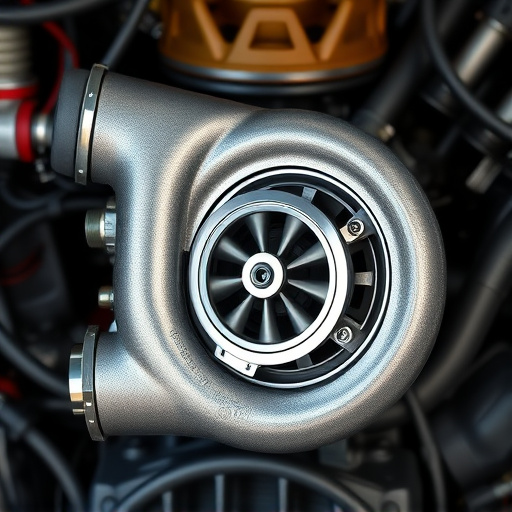

Power Stop brakes are a cutting-edge technology designed to enhance braking performance and reduce wear on brake components. These advanced systems work by applying precise pressure to the brake pads, ensuring consistent and optimal contact with the rotor or drum. The basic function involves using hydraulic pressure generated by the vehicle’s fluid system to activate specialized calipers or wheel cylinders, which in turn press the pads against the rotating surface, thereby slowing or stopping the vehicle.

This innovative technology is particularly beneficial for drivers who frequently experience heavy braking demands, such as those with high-performance vehicles or those navigating challenging terrain. Unlike traditional brakes, Power Stop brakes can deliver more even and controlled pressure, leading to improved braking efficiency. This consistent performance also translates into extended lifespan for brake components, including pads, rotors, and suspension parts, thus potentially saving drivers money in the long run. Additionally, some models may incorporate features like corrosion-resistant materials or enhanced cooling capabilities, further enhancing overall brake system health.

The Impact on Brake Wear: Advantages and Potential Disadvantages

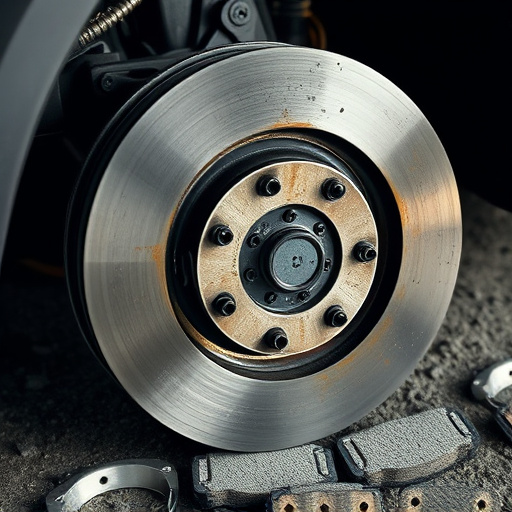

Power stop brakes have gained significant attention for their potential to transform driving dynamics and enhance safety. The primary advantage lies in their ability to reduce brake wear, a common issue with traditional braking systems. By employing advanced materials and engineering, power stop brakes can offer longer lifespan for critical components like brake pads, ensuring better value for vehicle owners over time. This technology is particularly beneficial for those who frequently drive in demanding conditions, such as heavy traffic or mountainous terrains, where consistent and intense braking is required.

However, while power stop brakes present compelling advantages, there are potential disadvantages to consider. The initial cost of installation might be higher compared to standard brake upgrades, which could deter budget-conscious consumers. Furthermore, the performance and longevity of power stop brakes heavily rely on regular maintenance and proper usage. Just like any sophisticated automotive system, factors like improper air intake systems, inadequate fluid levels, and neglectful driving habits can negatively impact their effectiveness, ultimately affecting overall brake wear and safety.

Maintenance Tips for Optimizing Power Stop Brakes' Lifespan and Reducing Wear

Regular maintenance is key to optimizing your power stop brakes’ lifespan and minimizing wear. First, ensure consistent brake fluid levels; top up as needed using a compatible fluid that meets the manufacturer’s specifications. Second, check for signs of corrosion or damage on brake pads and rotors, replacing them if necessary to prevent uneven wear. Third, inspect the condition of your vehicle’s intake components and coilover kits, as these can influence airflow and suspension stability, indirectly impacting brake performance. Keep these systems well-maintained to ensure optimal braking efficiency. Lastly, follow a structured maintenance schedule recommended by the vehicle manufacturer to address potential issues early on.

Power Stop brakes offer a compelling solution for reduced brake wear and improved performance. By utilizing advanced materials and design, these brakes can withstand high temperatures and friction, prolonging their lifespan and that of your vehicle’s other braking components. However, as with any automotive part, proper maintenance is key to reaping these benefits. Regular inspections, timely replacements, and adherence to manufacturer recommendations ensure optimal power stop brake performance and safety for years to come.